KIT, MOTOR PUMP DIESEL high pres., 80 m3/h max, 70m max, 4"

Valid Article

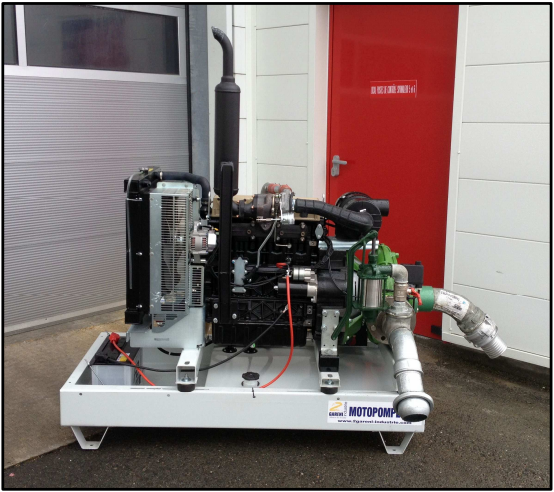

KIT, MOTOR PUMP DIESEL high pres., 80 m3/h max, 70m max, 4"

Definition

High pressure and high flow motor pump used as clear water suppressor for important differences in level or extensive pipe networks. Kit used in large camp settings (> 15000 persons) to create distribution system. Adaptable to most water networks (different diameters and pipe types). This kit is meant to supply water beyond the pre-treatment station.

Indications

MOTORPUMP CLOSED ARTICLE [Kohler KDI 2504TM + Rovatti F33P100K]

- Suction: Flange ND100 (4”) ;

- Delivery: Flange ND80 (3”) Pump + engine mounted on a chassis

- Non self-priming

- Maximum total head: 70m

- Maximum yield: 130mᶟ/h

Specifications

Components

▪ KIT

The kit is composed of 9 modules containing all the accessories and consumables required for the functioning and maintenance of the pump

- Module Consumables 1000 hours for Kohler KDI2504TM

- Module Assembly, Suction Side, 4” ND100

- Module Assembly, Delivery Side, 3” ND80

- Module Hand Pump, for priming

- Module Connection Potable water network 3”, ND80

- Module Wheel Towing

- Module Protection Frame + Grid

- Module Flat Hoses 4” 400m

- Module Couplings adaptation

▪ RELATED MODULES (optional)

According to the field constraints and initial assessment

- Kit Reservoir 30 m3 metallic frame

- Kit Water Tank 45-70-90mᶟ (Even / Oxfam)

- Module Additional flat hoses 4” (ring of 400m)

- Kit Dosing station (dosapack) under development

▪ TRANSPORT FEATURES

- Dismountable trailer Compatible with Land Cruiser hook

- Approved for concrete road/track

- Fit between Land Cruiser wheel passage

- Fit into a Cessna Caravan plane (specific measures for loading)

Instructions for use

Kit supplied with detailed operator manuals (a technician should be able to do the installation and to run the motor pump). Train the staff in proper operation and maintenance.

Remarks

The high flow and high pressure motor pump kit was designed to be used during the first phase of an emergency (3-6 months). However considering the operating costs and the need of supervision, it can be considered for long term water supply project.

References tools

Kit supplied with user manuals and documentation

- Engine : refer to “KOHLER KDI 2504TM User Manual” + “Instructions for installation and use Box R713”

- Pump : refer to “ROVATTI Instruction of use and maintenance Serie FL - FK - FP - FQ - FS - FNSF” + “Declaration of conformity”

- 2Gareni : refer to “Notice d'instructions - Groupe motopompe et moteur d'entrainement”

For more detailed informations and instructions refer to :

- Public Health Engineering in Precarious Situations, chapters T.B. 2.25 Centrifugal pumps and T.B. 2.28 Motor pump kit installation

- Gravity Flow Support, MSF-F Fiches techniques d'utilisation des motopompes, Juin 2001, Gilles Isard, MSF-F

- W.H.S. Technical Support Department in OCG and/or to W.H.S. Technical Advisor in MSF Logistique

Precautions for Use

To be used for pumping clear water only (turbid water would damage the pump).

Before you put the motor pump into operation for the first time, make sure it is installed on a flat surface and located in a ventilated and rainproof shelter.

The motor pump is delivered without oil, coolant and battery acid Requires special precautions when loading.

Specific precautions to be taken when operating the motor pump especially when mounted in series.