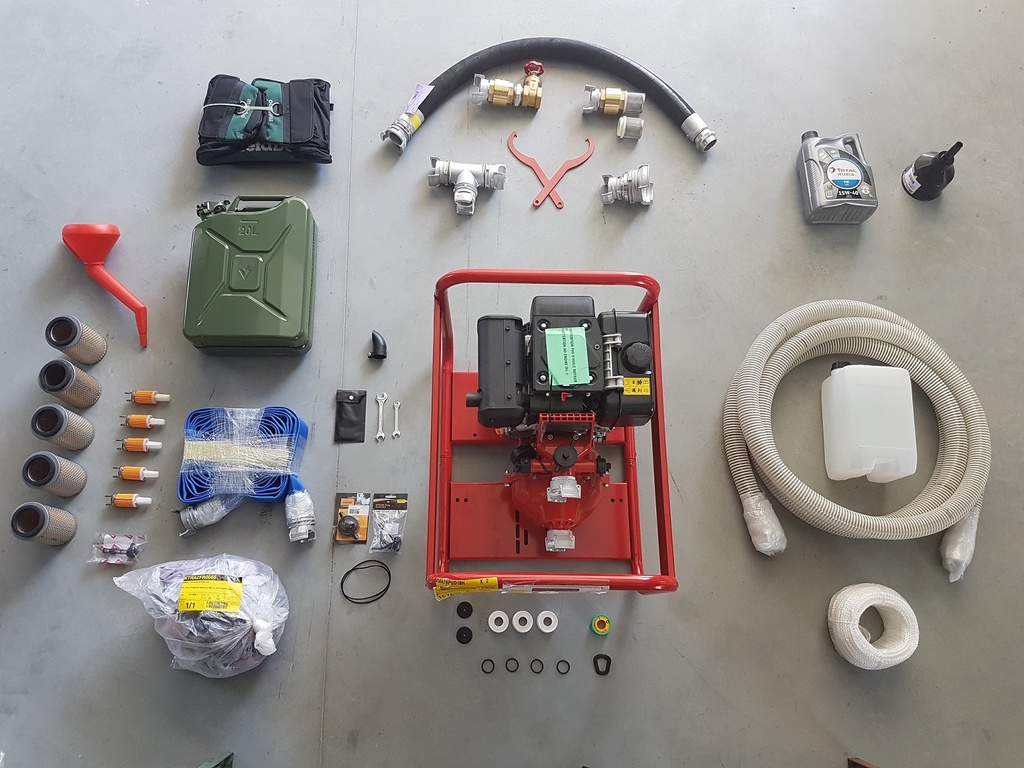

KIT, MOTOR PUMP, DIESEL, 18 m³/h (Davey + Yanmar)

Valid Article

KIT, MOTOR PUMP, DIESEL, 18 m³/h (Davey + Yanmar)

Definition

High pressure diesel motor pump used only with clear water for important differences in level/height or long distance pipe networks.

Indications

MOTOR PUMP

CLOSED ARTICLE (Davey DEF5210YECE + Yanmar)

- Guillemin coupling 2" (ND50) at inlet and outlet

- Pump + engine mounted on a frame

- Self-priming

- Maximum total head: 90 m

- Maximum yield: 32 m3/h

KIT

The kit contains all the accessories and consumables required for the functioning and maintenance of the pump.

Instructions for use

To be used for pumping clear water only (turbid water would damage the pump).

Kit supplied with user manual.

Check that the performance curve of the pump suits your situation:

- Fill the oil pan prior to first use and check the level daily.

- Check the fuel quality (no water or impurities). Use the funnel with water retention filter to fill the tank.

- For the suction, use only the long spiral hose and strainer supplied in the kit.

- On the discharge side, the 2" outlet assemblies (short spiral hose + gate valve and non-return valve) must be connected in between the pump and the pipeline to ease the disconnection of the pump and to prevent water hammering.

- It is possible to create a large distribution system with the pump delivering water from a reservoir directly to several tap stands without needing gravity. In this case, it is necessary to integrate the little piece of spiral hose and the T-piece (included in the kit) for the recirculation of water towards the reservoir when all taps are closed.

- Prime the pump with water before starting.

- Train the staff in proper operation, follow-up and maintenance of the pump.

- Maintenance: every 100 hours. Fill in the maintenance logbook.

For more detailed information and instructions see also the Owner's manual (integrated in kit) and "Public Health Engineering in Precarious Situations", MSF, 2nd edition, 2010:

- T.B. 2.25 Centrifugal pumps

- T.B. 2.28 Motor pump kit installation

Storage

Always store pump with all liquids drained (no water in housing of pump, no fuel in tank of engine) and clean the pump before storing.

![[KWATMPUD18P] (mod. diesel motor pump, 18m³/h) PUMP + PARTS + CONSUMABLES](/web/image/product.template/551950/image_256/%5BKWATMPUD18P%5D%20%28mod.%20diesel%20motor%20pump%2C%2018m%C2%B3-h%29%20PUMP%20%2B%20PARTS%20%2B%20CONSUMABLES?unique=c049ea7)

![[KWATMPUD18T] (module diesel motor pump, 18m³/h) TOOLS + ACCESSORIES](/web/image/product.template/551970/image_256/%5BKWATMPUD18T%5D%20%28module%20diesel%20motor%20pump%2C%2018m%C2%B3-h%29%20TOOLS%20%2B%20ACCESSORIES?unique=c049ea7)

![[KWATKTOO1--] KIT, WATER TOOLS, basic](/web/image/product.template/551982/image_256/%5BKWATKTOO1--%5D%20KIT%2C%20WATER%20TOOLS%2C%20basic?unique=aca794f)

![[KWATMHOS02-] MODULE, ADDITIONAL HOSES + couplings, 2"](/web/image/product.template/551926/image_256/%5BKWATMHOS02-%5D%20MODULE%2C%20ADDITIONAL%20HOSES%20%2B%20couplings%2C%202%22?unique=60e3982)

![[KWATZTF0033] MAINTENANCE MODULE 100 h., for L100/davey 93267](/web/image/product.template/567800/image_256/%5BKWATZTF0033%5D%20MAINTENANCE%20MODULE%20100%20h.%2C%20for%20L100-davey%2093267?unique=f80c915)