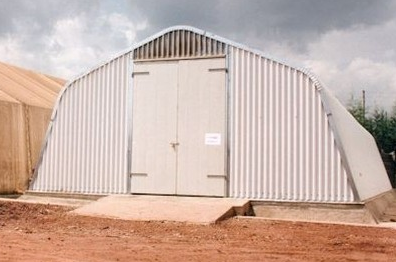

WAREHOUSE (Flospan AF930) 9.3x32m insulated

NST

CSEMTRANF32

Valid Article

HS Code:

732690

Last Updated on:

07/11/2024, 20:29:13

WAREHOUSE (Flospan AF930) 9.3x32m insulated

Form

- The Flospan frameless building system is one the lightest steel building system in the world, and the easiest to erect. This article comes with the insulation.

- Building Dimensions for Building Model A930:

- Building Span: 9.3m

- Building Length: 32m (The length can be modified by adding or removing flospans of lengths 0.9m to the main baby flospan, please contact the supply center or the construction advisor for such modifications).

- External Ridge Height: 4.8m

- Eaves Height: 3.2m

- Double Door Height: 3.7m

- Double Door Width: 2.6m

- Personnel Door: Height: 2m

- Personnel Door Width: 0.9m

- Floor Area: 221m2

- Building Volume: 768m3

- Wall Inclination from Vertical: 18 deg

- Roof Pitch: 24 deg

- Specifications:

- Cladding Sheet Materials: All cladding material is manufactured from “Galvatite”, a hot dipped zinc coated steel. The substrate is of grade Fe E280G commercial quality mild steel with a minimum yield stress of 280 N/mm2 . Galvanised coating is to a minimum thickness of 275 g/m2 with a conventional spangle finish.

- Base Framework and Door Frames Material: All framework materials are from cut lengths of hot rolled mild steel of HR15 commercial quality to comply with the provisions of BS 1449: Part 1: 1972. All components are pre-formed and punched where necessary and welding operations carried out as required prior to hot dip galvanising to provide a continuous coating of zinc.

- Door and Window Component Material: Galvanised Steel or Colour coated double hinged doors with hasp and staple fixing. These materials are to an identical specification to that given for cladding sheet materials above.

- Gable End Verge Trim Materials: Verge trims are manufactured from 16G (1.6mm) thick “Galvatite” materials to identical specifications as given for cladding sheet materials above.

- Foundation Bolts: M16 x 140mm “through bolts” for fixing to a concrete slab.

Fit

- Flospans can be built on different types of foundations, depending on intended use, ground conditions, and deployment duration, and can either be fixed directly to bare ground by using ground spikes or on a concrete slab by using foundation bolts.

- Ground Spikes: 600mm long 20mm diameter foundation spikes with hot forged dome head and hot forged point with red oxide finish for fixing to firm level ground.

- Insulation: Double steel skin with 80mm fiberglass, giving a “building within a building” or a board-based system using fiberglass and plasterboard with a mineral fiber suspended ceiling.

Function

- Pre-engineered: Flospans are fully engineered for assembly by hand with no cranes or special equipment. No drilling or cutting is required.

- Redeployable: All the holes are pre-drilled and Flospans can be moved and reused with no loss of materials.

- Fast and Simple: It can be erected in three days – and still be there thirty years later.

- Fast and Flexible: Flospans can be erected on bare ground without foundations, and they will withstand hurricane-force winds and snow loads.

- Long Life: Flospans have an overall life of forty years or more.

![[CSEMTRANF9S] (Flospan warehouse) SPIKES for fixation to the ground](/web/image/product.template/549088/image_256/%5BCSEMTRANF9S%5D%20%28Flospan%20warehouse%29%20SPIKES%20for%20fixation%20to%20the%20ground?unique=92524b7)

![[CSEMTRANF9T] (Flospan warehouse) TOOLS AND SCAFFOLD TOWER](/web/image/product.template/549087/image_256/%5BCSEMTRANF9T%5D%20%28Flospan%20warehouse%29%20TOOLS%20AND%20SCAFFOLD%20TOWER?unique=92524b7)

![[CSEMTRANFTO] (Flospan warehouse) TOOLS, 28 pcs, set](/web/image/product.template/582194/image_256/%5BCSEMTRANFTO%5D%20%28Flospan%20warehouse%29%20TOOLS%2C%2028%20pcs%2C%20set?unique=9ff2b3b)