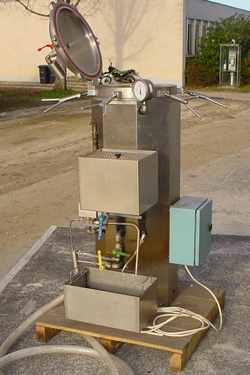

AUTOCLAVE TBM 90 l, vertical, 220V/380V/gas/kerosene, drying

Valid Article

AUTOCLAVE TBM 90 l, vertical

Definition

A device designed for total elimination and/or inactivation of microorganisms from medical devices and related products using pressurized steam (i.e., moist heat) as the sterilizing agent.

Manually-operated 90-litre single-chamber vertical autoclave, designed to function on 3 different types of energy sources (gas, kerosene and electricity) and no running water. The energy sources can be used separately or in combination, according to the power supply situation.

Synonym

Daguerre autoclave

Specifications

Quality standards

- EN 285, 2016, +A1 2021 Sterilization - Steam sterilizers - Large sterilizers

- EN 13445, 2021, Unfired Pressure Vessels (parts 1-5)

- EN IEC 61010-2-040, 2020, edition 3, Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-040 Particular requirements for sterilizers and washer-disinfectors used to treat medical materials

- ISO 17665-1, 2006, edition 1, (confirmed 2016) Sterilization of health care products - Moist heat - Part 1: Requirements for the development, validation and routine control of a sterilization process for medical devices

Technical specifications

- Vertical model

- Stainless steel

- Inner dimensions: 40 cm Ø x 70 cm high

Heating

- Electricity (220 V - 380 V, power: 4.5 kW)

- Kerosene

- Gas

These heating sources can be used separately or together (electricity + kerosene, or electricity + gas). This is especially useful in MSF contexts where the power supply is often unreliable.

The autoclave can be set by simple switching to operate

- normally with a power of 4,500 W

- with a reduced power of 3,000 W

- with 1,500 W to supplement another heating source.

Drying

The condensation system incorporated in this autoclave is specially designed for use without electricity or running water, as both are liable to be available only intermittently in many outlying hospitals.

Use

The valves are of different colours to make the use easier. Operating instructions in English and in French are attached to the autoclave. Pressure and temperature measurements are indicated in the different units that are used in the world.

Construction

All the mechanisms were designed to keep maintenance to a minimum and prevent breakdowns.

Since several years, TBM/Aftech/Sterimed does not manufacture the doors (or covers) anymore, but buys an existing product and welds it on its autoclave.

4 kinds of covers were successively used:

- cover TBM Daguerre

- this rectangular gasket became obsolete

- cover Boyer

- round profile gasket Ø 6 mm

- internal Ø 403 mm

- MSF code: ESTEAUTS927/ ESTEAUTO90M ref. 190095

- cover OPA

- round profile gasket Ø 9 mm

- internal Ø 408 mm

- MSF code: ESTEAUTS928/ ESTEAUTO90N ref. 190089

- New cover 2011

- gasket ref. 191019

- MSF code: ESTEAUTS904/ ESTEAUTO904

When ordering a spare gasket, please specify the dimension of the gasket and/or the serial number of the autoclave.

Supplied with the Article

- 4 HEPA filters

- supplier's user manual

To be Ordered Separately

- timer

- TST indicator strips

- autoclave steam indicator tape

- plastic jerry can (20 litres)

- crepe paper sheets

Instructions for use

Installation

ELECTRICITY

- The electrical wiring should be adapted to the available current (380V three-phase, 220V three-phase, 220V single-phase) by modifying the connections position inside the electrical box.

KEROSENE / GAS

- The autoclave must be installed in a ventilated area, but protected from drafts.

- Make sure the flame is not too close to the base of the autoclave.

- If the space does not afford sufficient ventilation, the chimney should be connected to the outside.

Precautions for Use

- WARNING: never heat the autoclave without water or when the water level is insufficient.

All models have a safety device which switches off the power supply if the water level is insufficient. In this case, after cooling down with the green valve open, add water until the surplus evacuates through the green valve and wait until the system resets (the sensor must be cold). However, this safety is not total, and heating with an insufficient water level will always end by destroying the heater elements and the security thermostat. - Use FILTERED water, non salt, low or non chlorinated, and preferably soft water, for example tap water or rainwater (never the water recovered in the autoclave from a previous sterilization cycle since the limestone concentration is particularly high).

- Once a week, remove limestone build-up by heating the (empty) autoclave with water and vinegar.

- Never use chlorinated products for cleaning the autoclave.

- It is recommended to unscrew the box for cotton (or gauze compresses) located on the lid of the autoclave and to replace it with an air filter to filter the air which is reintroduced into the autoclave after drying. Change the HEPA filter every 6 months (see related articles below).

- As this is a completely manual-driven apparatus, the operators must absolutely follow the instructions in every detail to guaranty a proper sterilization and prevent accidents (burns, explosion, etc.).

- Before loading the autoclave, be sure that the articles to be sterilized were correctly pre-disinfected, washed, dried, controlled and packed.

MSF requirements

This autoclave is specially suited to the conditions of regional hospitals, because of its flexibility of power source, its special drying process, its ease of use and its reliable design.

Heating recommendations

Combined heating

Some electrical systems (with a low power generator) are not powerful enough for position 3 (4,500 W). In this case, position 2 (3,000 W) should be used.

Position 1 (1,500 W) does not give enough heat for a sterilization cycle, but can be used in combination with another power source: electricity 1500 watts + kerosene (or gas) to give faster heating than with kerosene (or gas) alone.

Recommendations for reducing heat losses when using a burner

- Avoid exposing the autoclave to drafts.

- Find a balance between sufficient supply of air for good combustion and keeping hot air round the autoclave

(try closing halfway the heater door and/or the gas outlet.) - A sterilization cycle takes a ± long time, depending on the power of the heating source. Allow at least 2 hours with electric heating or kerosene heating with a correct burner (strong enough, foot pump). A less powerful burner without foot pump, can increase the time of the cycle up to 4 hours and even more.

Kerosene heating

- Use only a single burner heater. Never use a multiple burner heater (risk of fire).

- Fill 2/3 of the tank with filtered kerosene (do not use diesel).

- Make sure the different parts of the burner and tank are properly tightened together.

- Pump up the pressure (if foot pump, 3 bars maximum). Light the burner.

- Pump up the pressure again every 30 min; maximum heating requires maximum pressure.

NB: Certain models have a connection for an external pump. Such a pump is easier to use, but never exceed a pressure of 3 bars.

Heating settings

0: power off.

1: first element switched on (1,500 W at 220 V)

2: two elements switched on (3,000 W at 220 V)

3: three elements switched on (4,500 W at 220 V)

Electrical connections

The electrical connecting and the position of the strips must correspond to the type of current.

In any case, connect the earth (green/yellow terminal) to the common earth of the building using a conductor of 4 mm² diameter. If there is no common earth, sink an iron spike of minimum 1 cm diameter and 150 cm long (e.g. a concrete reinforcing rod) into the earth at the dampest possible spot.

Extra Tables

| code | label | Aftech | MDS |

| ESTEAUTA951 | (autoclave TBM 90 l) BASKET, stainless steel | AC0802 | 900807 |

| ESTEAUTA954 | (autoclave TBM 90 l) STAND for gaz burner | KI0061 | 700 025 |

| ESTEAUTA956 | (autoclave TBM 90 l) WRENCH 60mm, heater element take-off | 700015 | |

| ESTEAUTA957 | (autoclave TBM 90 l) GRID BOTTOM STERILIZATION CHAMBER | 300024 | 900972 |

| ESTEAUTA958 | (autoclave TBM 90 l) GRID CONDENSATION CONTAINER | KI0002 | 900973 |

| ESTEAUTS904 | (autoclave TBM 90 l) GASKET cover, Ø 13 mm | JO0003 | |

| ESTEAUTS9041 | (autoclave TBM 90 l) GASKET cover, Ø 13 mm, Manufacturer MDS | 200078 | |

| ESTEAUTS905 | (autoclave TBM 90 l) BOLT SET of BOYER DOOR, 2 handles | KI0071 | |

| ESTEAUTS908 | (autoclave TBM 90 l) VALVE 1/4th TURN RED | KI0510 | 600111 |

| ESTEAUTS909 | (autoclave TBM 90 l) VALVE 1/4th TURN YELLOW | KI0512 | 600111A |

| ESTEAUTS910 | (autoclave TBM 90 l) VALVE 1/4th TURN GREEN | KI0513 | 600111B |

| ESTEAUTS911 | (autoclave TBM 90 l) VALVE 1/4th TURN BLUE | KI0511 | 600111C |

| ESTEAUTS912 | (autoclave TBM 90 l) VALVE 1/4th TURN BLACK | KI0516 | 600111D |

| ESTEAUTS913 | (autoclave TBM 90 l) TIMER S43, 60 min | AC0290 | 240329 (400148 achat 2020) |

| ESTEAUTS914 | (autoclave TBM 90 l) PLATE + HANDLE for switch | KI0065 | |

| ESTEAUTS916 | (autoclave TBM 90 l) BRASS COIL | RE7401 | 900974 |

| ESTEAUTS917 | (autoclave TBM 90 l) DISCHARGE VALVE, 121°C | KI1122 | 800618 |

| ESTEAUTS918 | (autoclave TBM 90 l) DISCHARGE VALVE, 134°C | KI1134 | 800619 |

| ESTEAUTS919 | (autoclave TBM 90 l) ADAPTATION KIT | KI0010 | 800620 |

| ESTEAUTS920 | (autoclave TBM 90 l) MANOMETER | AC0001 | 300304 |

| ESTEAUTS921 | (autoclave TBM 90 l) CABLE, 5 m flex. 5 cond. + con. | KI2304 | 420027 |

| ESTEAUTS922 | (autoclave TBM 90 l) THERMOSTAT 60 to 200 °C | KI2016 | 300254 |

| ESTEAUTS923 | (autoclave TBM 90 l) DRAINAGE HOSE reinf. 5 m + collar | KI0081 | 700011 |

| ESTEAUTS924 | (autoclave TBM 90 l) HEATER ELEMENT, 4.5 KW | ELC1301 | 800806 |

| ESTEAUTS925 | (autoclave TBM 90 l) BULB, complete, blue | ELO109 | 400 073 |

| ESTEAUTS926 | (autoclave TBM 90 l) GASKET for heater device | 700004 | 200 715 |

| ESTEAUTS927 | (autoclave TBM 90 l) GASKET cover Boyer, Ø 6 mm | JO0002 | 200 077 |

| ESTEAUTS928 | (autoclave TBM 90 l) GASKET cover OPA, Ø 9 mm | JO0001 | |

| ESTEAUTS929 | (autoclave TBM 90 l) ELECTRICAL BOX, wiring, complete | ELC001 | 241947 (900952 achat 2020) |

| ESTEAUTS932 | (autoclave TBM 90 l) SAFETY VALVE | AC0004 | 800601 |

| ESTEAUTS933 | (autoclave TBM 90 l) SWITCH 4 positions, 3 poles | 240381 | |

| ESTEAUTS936 | (autoclave TBM 90 l) SET of LOCK, cover Boyer 2model,1handle | KI0072 | 730 045 |

| ESTEAUTS937 | (autoclave TBM 90 l) PULLEY SHAFT lock, cover Boyer,1 model | KI0071 | 730 044 |

| ESTEAUTS939 | (autoclave TBM 90L) 3pcs union inox 316L 2spigots DN15 1/2"G | pas créé | 310520 |

| ESTEAUTS940 | (autoclave TBM 90 l) SPACER TUBE | RE2087 | 700 029 |

| ESTEAUTS942 | (autoclave TBM 90 l) KIT PURGE, precycle eco | KI0082 | 700 030 |

| ESTEAUTS943 | (autoclave TBM 90 l) CABLE SEAL heater element M45 | JO0009 | |

| ESTEAUTS944 | (autoclave TBM 90 l) PFTE TUBE 500mm Ø12mm | KI0058 | |

| ESTEAUTS945 | (autoclave TBM 90 l) PFTE TUBE 500mm Ø16mm | KI0059 | |

| ESTEAUTS946 | (autoclave TBM 90 l) DRAIN PAN | KI300011 | 700 035 |

![[KMEDMAUT90-] MODULE, AUTOCLAVE, STEAM, TBM 90 l](/web/image/product.template/572100/image_256/%5BKMEDMAUT90-%5D%20MODULE%2C%20AUTOCLAVE%2C%20STEAM%2C%20TBM%2090%20l?unique=919fa2f)

![[CWATSEALTT9] TAPE (Teflon) 19mmx15m, 0.2mm thick, roll](/web/image/product.template/546611/image_256/%5BCWATSEALTT9%5D%20TAPE%20%28Teflon%29%2019mmx15m%2C%200.2mm%20thick%2C%20roll?unique=e0ce1ea)

![[ESTEAUTS803] (Matachana 80LR1,TBM) AIR FILTER,antibact/antiviral 41608.1](/web/image/product.template/568721/image_256/%5BESTEAUTS803%5D%20%28Matachana%2080LR1%2CTBM%29%20AIR%20FILTER%2Cantibact-antiviral%2041608.1?unique=79d43f4)

![[ESTEBURN1M-] BURNER, PRESSURE, kerosene, modified pump connect. 90l aut.](/web/image/product.template/568699/image_256/%5BESTEBURN1M-%5D%20BURNER%2C%20PRESSURE%2C%20kerosene%2C%20modified%20pump%20connect.%2090l%20aut.?unique=f7a81ba)

![[ESTEBURNGA1] BURNER, GAS, 8000 W, butane, dismountable tripod + HOSE 1.5m](/web/image/product.template/568701/image_256/%5BESTEBURNGA1%5D%20BURNER%2C%20GAS%2C%208000%20W%2C%20butane%2C%20dismountable%20tripod%20%2B%20HOSE%201.5m?unique=cd0a525)

![[PELEPLUGE5144] PLUG male, plastic, type E+F/EUR, 3P+N+E 16A, IP44](/web/image/product.template/550307/image_256/%5BPELEPLUGE5144%5D%20PLUG%20male%2C%20plastic%2C%20type%20E%2BF-EUR%2C%203P%2BN%2BE%2016A%2C%20IP44?unique=e83d873)

![[TVEAPUMP1HC] (pump, hand operated) CONNECTOR, flexible](/web/image/product.template/552972/image_256/%5BTVEAPUMP1HC%5D%20%28pump%2C%20hand%20operated%29%20CONNECTOR%2C%20flexible?unique=52839b9)

![[ESTEAUTA951] (autoclave TBM 90 l) BASKET, stainless steel](/web/image/product.template/568928/image_256/%5BESTEAUTA951%5D%20%28autoclave%20TBM%2090%20l%29%20BASKET%2C%20stainless%20steel?unique=79d43f4)

![[ESTEAUTA952] (autoclave TBM 90 l) INSTRUCTIONS FOR REPAIR](/web/image/product.template/568933/image_256/%5BESTEAUTA952%5D%20%28autoclave%20TBM%2090%20l%29%20INSTRUCTIONS%20FOR%20REPAIR?unique=bf3bad5)

![[ESTEAUTA953] (autoclave TBM 90 l) USER/INSTALLATION LEAFLET](/web/image/product.template/568935/image_256/%5BESTEAUTA953%5D%20%28autoclave%20TBM%2090%20l%29%20USER-INSTALLATION%20LEAFLET?unique=bf3bad5)

![[ESTEAUTA954] (autoclave TBM 90 l) STAND for gaz burner](/web/image/product.template/568930/image_256/%5BESTEAUTA954%5D%20%28autoclave%20TBM%2090%20l%29%20STAND%20for%20gaz%20burner?unique=79d43f4)

![[ESTEAUTA955] (autoclave TBM 90 l) TESTING AND MAINTENANCE INSTRUCTIONS](/web/image/product.template/568932/image_256/%5BESTEAUTA955%5D%20%28autoclave%20TBM%2090%20l%29%20TESTING%20AND%20MAINTENANCE%20INSTRUCTIONS?unique=9fe42ab)

![[ESTEAUTA956] (autoclave TBM 90 l) WRENCH 60mm, heater element take-off](/web/image/product.template/568943/image_256/%5BESTEAUTA956%5D%20%28autoclave%20TBM%2090%20l%29%20WRENCH%2060mm%2C%20heater%20element%20take-off?unique=a102877)

![[ESTEAUTA957] (autoclave TBM 90 l) GRID BOTTOM STERILIZATION CHAMBER](/web/image/product.template/568946/image_256/%5BESTEAUTA957%5D%20%28autoclave%20TBM%2090%20l%29%20GRID%20BOTTOM%20STERILIZATION%20CHAMBER?unique=649a5c2)

![[ESTEAUTA958] (autoclave TBM 90 l) GRID CONDENSATION CONTAINER](/web/image/product.template/568939/image_256/%5BESTEAUTA958%5D%20%28autoclave%20TBM%2090%20l%29%20GRID%20CONDENSATION%20CONTAINER?unique=649a5c2)

![[ESTEAUTS904] (autoclave TBM 90l) GASKET cover, round, Ø13mm MDS 200084](/web/image/product.template/568712/image_256/%5BESTEAUTS904%5D%20%28autoclave%20TBM%2090l%29%20GASKET%20cover%2C%20round%2C%20%C3%9813mm%20MDS%20200084?unique=fdc0157)

![[ESTEAUTS9041] (autoclave TBM 90l) GASKET cover, lip Ø13mm L1225mm MDS](/web/image/product.template/578681/image_256/%5BESTEAUTS9041%5D%20%28autoclave%20TBM%2090l%29%20GASKET%20cover%2C%20lip%20%C3%9813mm%20L1225mm%20MDS?unique=08e2bd4)

![[ESTEAUTS9042] (autoclave TBM 90l) GASKET cover, lip Ø13mm L1170mm Aftech](/web/image/product.template/582152/image_256/%5BESTEAUTS9042%5D%20%28autoclave%20TBM%2090l%29%20GASKET%20cover%2C%20lip%20%C3%9813mm%20L1170mm%20Aftech?unique=9b6e8ab)

![[ESTEAUTS905] (autoclave TBM 90 l) BOLT SET of BOYER DOOR, 2 handles](/web/image/product.template/568713/image_256/%5BESTEAUTS905%5D%20%28autoclave%20TBM%2090%20l%29%20BOLT%20SET%20of%20BOYER%20DOOR%2C%202%20handles?unique=f7a81ba)

![[ESTEAUTS908] (autoclave TBM 90 l) VALVE 1/4th TURN RED](/web/image/product.template/568739/image_256/%5BESTEAUTS908%5D%20%28autoclave%20TBM%2090%20l%29%20VALVE%201-4th%20TURN%20RED?unique=79d43f4)

![[ESTEAUTS909] (autoclave TBM 90 l) VALVE 1/4th TURN YELLOW](/web/image/product.template/568740/image_256/%5BESTEAUTS909%5D%20%28autoclave%20TBM%2090%20l%29%20VALVE%201-4th%20TURN%20YELLOW?unique=79d43f4)

![[ESTEAUTS910] (autoclave TBM 90 l) VALVE 1/4th TURN GREEN](/web/image/product.template/568737/image_256/%5BESTEAUTS910%5D%20%28autoclave%20TBM%2090%20l%29%20VALVE%201-4th%20TURN%20GREEN?unique=79d43f4)

![[ESTEAUTS911] (autoclave TBM 90 l) VALVE 1/4th TURN BLUE](/web/image/product.template/568738/image_256/%5BESTEAUTS911%5D%20%28autoclave%20TBM%2090%20l%29%20VALVE%201-4th%20TURN%20BLUE?unique=79d43f4)

![[ESTEAUTS912] (autoclave TBM 90 l) VALVE 1/4th TURN BLACK](/web/image/product.template/568744/image_256/%5BESTEAUTS912%5D%20%28autoclave%20TBM%2090%20l%29%20VALVE%201-4th%20TURN%20BLACK?unique=79d43f4)

![[ESTEAUTS913] (autoclave TBM 90 l) TIMER S43, 60 min](/web/image/product.template/568746/image_256/%5BESTEAUTS913%5D%20%28autoclave%20TBM%2090%20l%29%20TIMER%20S43%2C%2060%20min?unique=f7a81ba)

![[ESTEAUTS914] (autoclave TBM 90 l) PLATE + HANDLE for switch](/web/image/product.template/568742/image_256/%5BESTEAUTS914%5D%20%28autoclave%20TBM%2090%20l%29%20PLATE%20%2B%20HANDLE%20for%20switch?unique=2385626)

![[ESTEAUTS916] (autoclave TBM 90 l) BRASS COIL](/web/image/product.template/568743/image_256/%5BESTEAUTS916%5D%20%28autoclave%20TBM%2090%20l%29%20BRASS%20COIL?unique=e38e493)

![[ESTEAUTS917] (autoclave TBM 90 l) DISCHARGE VALVE, 121°C](/web/image/product.template/568732/image_256/%5BESTEAUTS917%5D%20%28autoclave%20TBM%2090%20l%29%20DISCHARGE%20VALVE%2C%20121%C2%B0C?unique=f7a81ba)

![[ESTEAUTS918] (autoclave TBM 90 l) DISCHARGE VALVE, 134°C](/web/image/product.template/568734/image_256/%5BESTEAUTS918%5D%20%28autoclave%20TBM%2090%20l%29%20DISCHARGE%20VALVE%2C%20134%C2%B0C?unique=f7a81ba)

![[ESTEAUTS919] (autoclave TBM 90 l) ADAPTATION KIT](/web/image/product.template/568659/image_256/%5BESTEAUTS919%5D%20%28autoclave%20TBM%2090%20l%29%20ADAPTATION%20KIT?unique=bf3bad5)

![[ESTEAUTS920] (autoclave TBM 90 l) MANOMETER](/web/image/product.template/568674/image_256/%5BESTEAUTS920%5D%20%28autoclave%20TBM%2090%20l%29%20MANOMETER?unique=f7a81ba)

![[ESTEAUTS921] (autoclave TBM 90 l) CABLE, 5 m flex. 5 cond. + con.](/web/image/product.template/568675/image_256/%5BESTEAUTS921%5D%20%28autoclave%20TBM%2090%20l%29%20CABLE%2C%205%20m%20flex.%205%20cond.%20%2B%20con.?unique=e38e493)

![[ESTEAUTS922] (autoclave TBM 90 l) THERMOSTAT 60 to 200 °C](/web/image/product.template/568671/image_256/%5BESTEAUTS922%5D%20%28autoclave%20TBM%2090%20l%29%20THERMOSTAT%2060%20to%20200%20%C2%B0C?unique=51040a4)

![[ESTEAUTS923] (autoclave TBM 90 l) DRAINAGE HOSE reinf. 5 m + collar](/web/image/product.template/568672/image_256/%5BESTEAUTS923%5D%20%28autoclave%20TBM%2090%20l%29%20DRAINAGE%20HOSE%20reinf.%205%20m%20%2B%20collar?unique=51040a4)

![[ESTEAUTS924] (autoclave TBM 90 l) HEATER ELEMENT, 4.5 KW](/web/image/product.template/568678/image_256/%5BESTEAUTS924%5D%20%28autoclave%20TBM%2090%20l%29%20HEATER%20ELEMENT%2C%204.5%20KW?unique=4f50bf8)

![[ESTEAUTS925] (autoclave TBM 90 l) BULB, complete, blue](/web/image/product.template/568679/image_256/%5BESTEAUTS925%5D%20%28autoclave%20TBM%2090%20l%29%20BULB%2C%20complete%2C%20blue?unique=2385626)

![[ESTEAUTS926] (autoclave TBM 90 l) GASKET for heating device](/web/image/product.template/568676/image_256/%5BESTEAUTS926%5D%20%28autoclave%20TBM%2090%20l%29%20GASKET%20for%20heating%20device?unique=84739e0)

![[ESTEAUTS927] (autoclave TBM 90l) GASKET cover Boyer, Ø6mm](/web/image/product.template/568677/image_256/%5BESTEAUTS927%5D%20%28autoclave%20TBM%2090l%29%20GASKET%20cover%20Boyer%2C%20%C3%986mm?unique=f7a81ba)

![[ESTEAUTS928] (autoclave TBM 90 l) GASKET cover OPA, Ø 9 mm](/web/image/product.template/568670/image_256/%5BESTEAUTS928%5D%20%28autoclave%20TBM%2090%20l%29%20GASKET%20cover%20OPA%2C%20%C3%98%209%20mm?unique=5aa2116)

![[ESTEAUTS929] (autoclave TBM 90 l) ELECTRICAL BOX, wiring, complete](/web/image/product.template/568680/image_256/%5BESTEAUTS929%5D%20%28autoclave%20TBM%2090%20l%29%20ELECTRICAL%20BOX%2C%20wiring%2C%20complete?unique=bd18be0)

![[ESTEAUTS932] (autoclave TBM 90 l) SAFETY VALVE](/web/image/product.template/568697/image_256/%5BESTEAUTS932%5D%20%28autoclave%20TBM%2090%20l%29%20SAFETY%20VALVE?unique=e38e493)

![[ESTEAUTS933] (autoclave TBM 90 l) SWITCH 4 positions, 3 poles](/web/image/product.template/569430/image_256/%5BESTEAUTS933%5D%20%28autoclave%20TBM%2090%20l%29%20SWITCH%20%204%20positions%2C%203%20poles?unique=5d950e6)

![[ESTEAUTS936] (autoclave TBM 90 l) SET of LOCK, cover Boyer 2model,1handle](/web/image/product.template/570416/image_256/%5BESTEAUTS936%5D%20%28autoclave%20TBM%2090%20l%29%20SET%20of%20LOCK%2C%20cover%20Boyer%202model%2C1handle?unique=3f40535)

![[ESTEAUTS937] (autoclave TBM 90 l) PULLEY SHAFT lock, cover Boyer,1 model](/web/image/product.template/570419/image_256/%5BESTEAUTS937%5D%20%28autoclave%20TBM%2090%20l%29%20PULLEY%20SHAFT%20lock%2C%20cover%20Boyer%2C1%20model?unique=8dd3c0c)

![[ESTEAUTS940] (autoclave TBM 90 l) SPACER TUBE](/web/image/product.template/570593/image_256/%5BESTEAUTS940%5D%20%28autoclave%20TBM%2090%20l%29%20SPACER%20TUBE?unique=bd202d1)

![[ESTEAUTS943] (autoclave TBM 90 l) CABLE SEAL heater element M45,](/web/image/product.template/572985/image_256/%5BESTEAUTS943%5D%20%28autoclave%20TBM%2090%20l%29%20CABLE%20SEAL%20heater%20element%20M45%2C?unique=5fe8296)

![[ESTEAUTS946] (autoclave TBM 90 l) DRAIN PAN](/web/image/product.template/569987/image_256/%5BESTEAUTS946%5D%20%28autoclave%20TBM%2090%20l%29%20DRAIN%20PAN?unique=eea1eaf)

![[ESTEAUTS947] (autoclave TBM 90 l) HOSE RESTAURATION KIT, complete, KI0055](/web/image/product.template/587400/image_256/%5BESTEAUTS947%5D%20%28autoclave%20TBM%2090%20l%29%20HOSE%20RESTAURATION%20KIT%2C%20complete%2C%20KI0055?unique=75f5265)